Are you ready to learn how to create custom sublimation tiles that you can use in your home? I’m going to test a few different ways of sublimating tiles so we can see which method works best.

If you’ve struggled sublimating on tile, this tutorial is sure to help! If you’re new to sublimation, my Beginner’s Guide to Sublimation is a great place to start your sublimation journey.

In this tutorial, I’m going to show you how to sublimate a tile that can be added to a cheeseboard and also how to make tiles that you can actually use as accents in your home.

You can watch me make these sublimation tile projects by pressing play on the video below.

How to Make Custom Sublimation Tiles

We’re going to make these sublimation tiles in a couple of different ways. Each process works, so if you have supplies on hand for one method, go ahead and use that one.

Supplies Used

Remember, we’re using a couple of different methods. You don’t need all the supplies. Make sure to read through and get the supplies you need for the method you’re using.

- Free Sublimation Files

- Sublimation Tiles (from Amazon)

- Sublimation Tile (matte finish)

- Sublimation Cheese Board

- Brother Sublimation Printer

- Sublimation Paper

- Heat Press

- Lint Roller

- Heat Resistant Tape

- Heat Resistant Gloves

- Tape Dispenser

- Protective Paper

- Heat Resistant Mat

- Nomex Pad

- Green Rubber Mat

- White Silicone Mat

Sublimation Tile Types

Sublimation tiles need to have a sublimation coating on them. You can’t just buy a tile at the hardware store and use it for sublimation.

If you’ve struggled with sublimation tiles, make sure you’re using a sublimation blank.

I’m using sublimation tiles from Amazon and a matte sublimation tile from Johnson Plastics Plus. I’m also testing a sublimation tile that can be added to a cheeseboard.

Sublimation Pads

Because sublimation tiles can be rounded on the edges you may have some pressing issues. Let’s look at the different pads you can use to get the best results.

Nomex Pad

When using a Nomex pad you’ll place the pad on the bottom platen in the heat press. Place the protective paper on top of the pad and then add the sublimation tile with sublimation print taped into place face down on the Nomex pad.

The Nomex pad allows the tile to squish down into the pad so you get consistent pressure even on the rounded edges.

Rubber Pad

The next pad option I’m testing is the green rubber pad. I’ve used this for several years and it’s heat conductive.

When using the rubber pad you place it on top of the sublimation blank. It will conform to the tile shape and conduct the heat throughout the rubber pad.

This pad is expensive and often sells out which brings us to the next pad option.

White Silicone Mat

Because the green rubber pad can be hard to find I decided to test this silicone mat. It’s supposed to do the same thing as the green pad and is a lot less expensive.

You’ll use the silicone mat just like the rubber pad, add the mat to the top of the blank and the mat will conform around the tile and the silicone will conduct the heat through the mat.

I’m going to test all three pads on the Amazon tile first so I can compare how they do.

Step 1. Prep Tile

For each different mat, we’ll prep the tile in the same manner.

First, clean the tile. You can use a lint roller or rubbing alcohol and a cloth. Make sure the tile is completely dry before adding the print to the tile.

Next, you need to make sure the tiles are at room temperature. If they’re cold or hot it can impact the sublimation results.

If the tile is cold, you can add it to your heat press and hover the heat plate over the tile to bring it up to room temperature.

Add the sublimation print to the tile and secure it in place with heat-resistant tape.

I like my print to be slightly oversized so the print transfers to the sides. Don’t get tape on the side of the tile or it will prevent the design from transferring.

Step 2. Press Sublimation Tiles

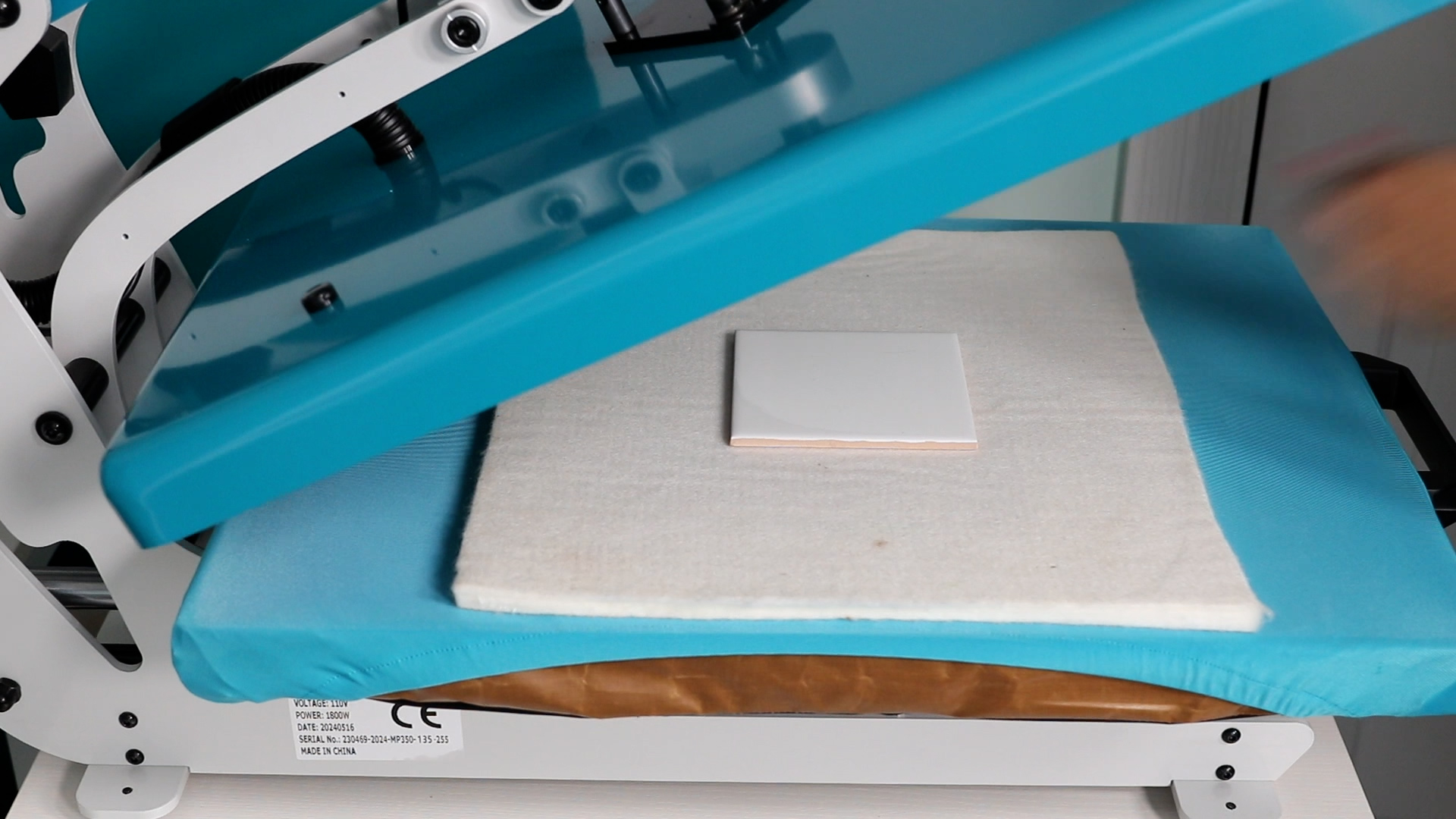

Protective paper needs to be added to the top and bottom of the sublimation tile.

Because I wanted the process to be the same for each tile I am preheating the pad each time so the inside of the press is very hot, even the bottom surface.

You also want to check the pressure and get that right before pressing. Use a spare tile to adjust the pressure. You want heavy pressure when pressing sublimation tiles.

I’m pressing each tile at 400 degrees for 400 seconds.

Pressing with a Nomex Pad

With the Nomex pad inside, close the heat press and preheat the press with the pad inside.

Open the press and add protective paper on top of the Nomex pad. Next, place the tile sublimation print down on top of the protective paper and cover it with another sheet of protective paper.

Press for the full time and then remove it and place it on a heat-resistant mat to cool.

Pressing with a Green Rubber Pad

For the green rubber pad, we’re going to preheat the rubber pad and adjust the pressure for the tile.

Add protective paper to the bottom platen and place the sublimation tile print side up on top.

Place another sheet of protective paper on top and cover with the rubber pad.

Press for the full time and then remove the tile and place it on top of a heat-resistant mat to cool.

Pressing with a White Silicone Pad

The silicone sheet came with a protective sheet on it that isn’t heat resistant, so you’ll want to remove that before pressing.

The process for using the white silicone pad is the same as using the rubber pad.

For the first press, I was nervous that the silicone pad might melt so I covered it with protective paper. The silicone pad did not melt so I didn’t need to do that on any of the other projects I made.

Press at 400 degrees for 400 seconds and then remove it from the heat press and place it on a heat-resistant mat to cool.

Pressing without a Mat

For the last test, I pressed with no pad or mat just to see what would happen.

I added a sheet of protective paper to the bottom platen and then placed the tile on top with the sublimation print on top.

Add another sheet of protective paper to the top of the tile and press for 400 seconds at 400 degrees.

Step 3. Finishing the Sublimation Tiles

Remove the sublimation print from the tile. This can be done while the tile is still warm if you wear heat resistant gloves.

Then just allow the tile to cool and it is ready to use. No sealing or additional process is required for using these tiles indoors.

Which Pad Works Best?

Now let’s look at the results we got with each different method.

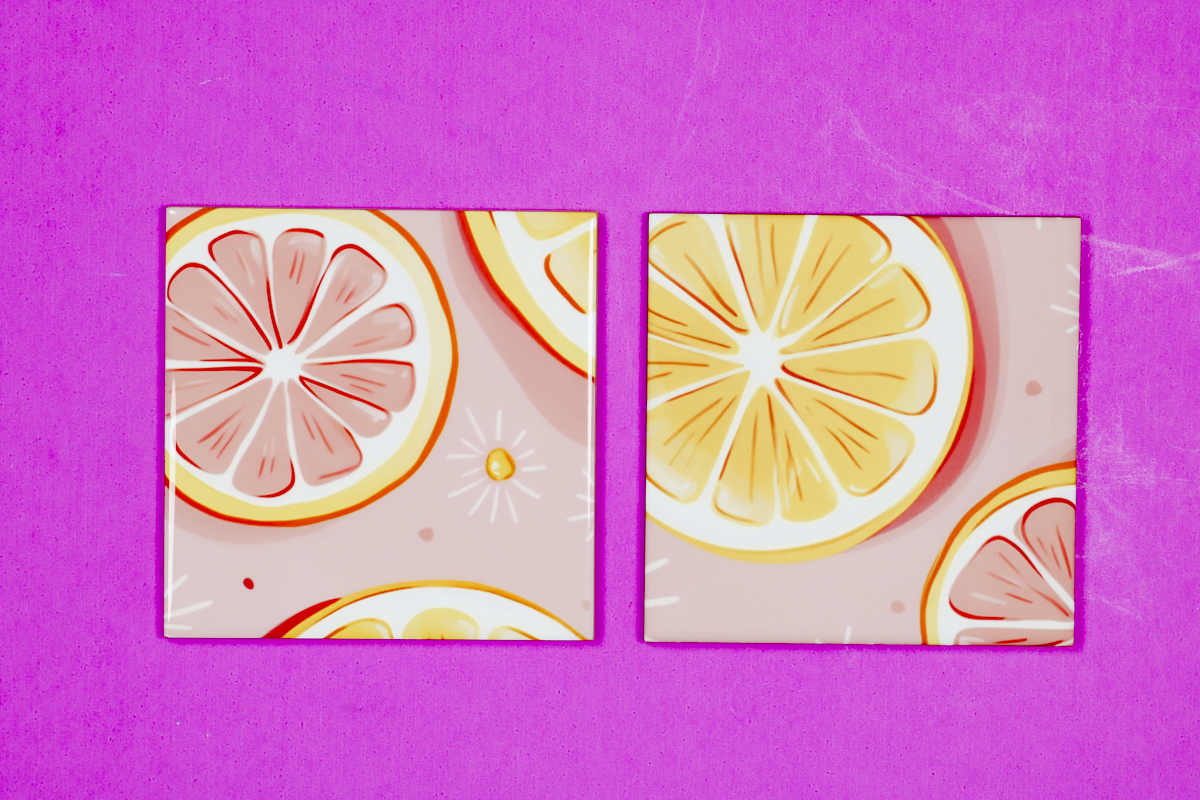

The top left tile is the one made with the Nomex Pad. It’s bright and vibrant, and the edges look amazing.

The top right tile is the tile made with the green rubber pad and it looks just as good as the tile with the Nomex pad.

On the bottom left is the white silicone mat tile and it also turned out perfectly. I’m really happy with this method. Since it was new to me I wasn’t sure how it would do but this tile looks just as good as the Nomex and Rubber pad tiles.

It’s hard to see in the photo but the bottom right tile is the tile I did without any pads. The edges are okay and the print did transfer but it is very dull compared to the other tiles. I thought some of the paper may have stuck to the tile but even after scrubbing it, it’s still very dull.

I would not recommend pressing a tile without using one of the pads I tested today.

More Sublimation Tile Project Ideas

Now that I have tested all the different pressing methods I am going to make a couple of projects.

I am going to use the white silicone mat for these projects because it is the least expensive of the pads you can buy. Since it worked so well I’m excited to try it on other tile blanks.

First, I’m going to make another sublimation tile, this one has a matte finish.

Matte Sublimation Tile

The process for these other tile projects is the same as we did before. We need to preheat the press to 400 degrees and we want to have the press closed with the mat inside so everything is hot.

Adjust the pressure with a blank tile inside so the pressure is correct. With the heat press ready we can add the sublimation tile sandwich.

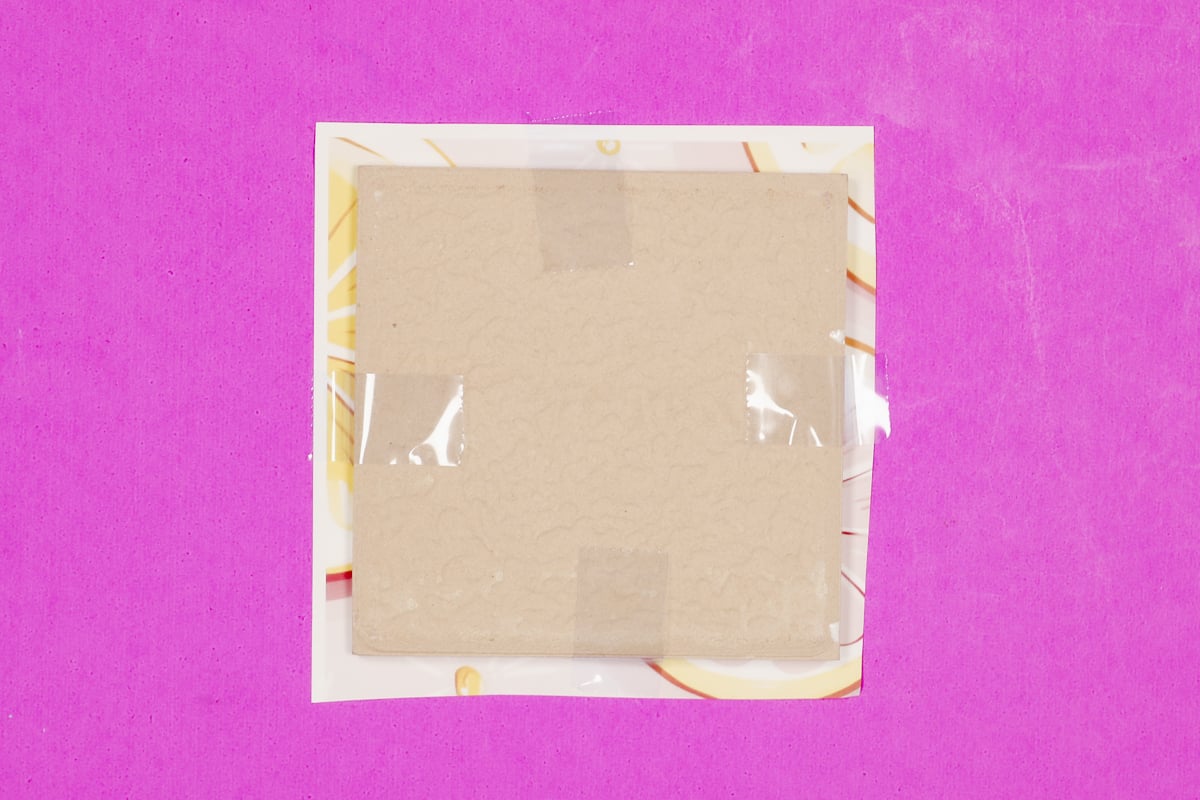

Add protective paper to the bottom of the heat press, and place the sublimation tile on top with the sublimation print taped into place facing up. Top with another piece of protective paper and add the white silicone to the top.

Close the press and press at 400 degrees for 400 seconds.

When the time is up, remove the tile and move it to a heat-resistant mat to cool.

I’m really happy with how this tile turned out. In the photo above the tile on the left is one of the glossy tiles I pressed before. The tile on the right is the matte tile. I was worried about the edges because it’s a bit more rounded than the glossy tiles but the design transferred beautifully.

Even with the matte finish the image is vibrant and really pops off the tile.

Sublimation Tile Cheeseboard

The cheeseboard tile is the largest tile I’ve pressed today.

The process is the exact same as all the other tiles. You do take the tile out of the cheeseboard to press it. Don’t try to press it in the board.

Even though the tile is larger I pressed it for the same time and temperature and it worked great.

Add the tile to the board to assemble the cheeseboard once it has cooled. To clean it you can just remove it the tile and wipe everything down.

The sublimation print is very vibrant and I love this design with the wood.

The Best Way to Make Sublimation Tiles

Now that we’ve looked at all these different pressing options which one would I recommend?

I would recommend any of the three pads. The only method I wouldn’t recommend today is not using a pad.

If you already own a Nomex pad or a green rubber pad, you can use those. If you don’t have one of those, the white silicone mat did an awesome job and is a lot less expensive.

I hope I’ve answered any questions you have on making sublimation tiles. If you have any additional questions, leave them in the comments and I’ll get those answered for you.