Are you throwing a party or looking for a fun gift idea? Today I’m going to show you 2 ways to make custom balloons. I am using mylar balloons for this project and will show you how to customize them with vinyl and white toner prints.

You can learn more about white toner printers and how they work in my What is white toner printing tutorial.

Whether you have a Cricut machine and want to add vinyl to mylar balloons or you’re looking for something with multiple colors like a white toner print this tutorial will help.

You can watch me make both custom balloon types by pressing play on the video below.

How to Make Custom Balloons with Vinyl

For today’s tutorial, I am using a small mylar balloon but you can use these same steps for any size balloon.

Supplies Used to Make a Custom Balloon with Vinyl

Step 1. Prepare the Design

I am using the Cricut Value Vinyl for today’s project. You can use any type of vinyl but I think permanent would last the longest.

Before you cut out the vinyl, you need to make sure you know what size to make your design. As you can see in the photo below when the balloon is deflated my design looks rather small. When it’s blown up the design takes up almost the whole surface.

Both of these designs are the exact same size. My design is about half the size of the widest part of the balloon and I think that is a good size to use.

Use your Cricut to cut the design out and then using a weeding tool weed out all of the outside and the centers of any letters.

Step 2. Apply Transfer Tape

Transfer Tape, even regular grip transfer tape, may be too sticky for the application to the balloon. To make the transfer tape less sticky apply it to a cloth or even your shirt.

When it’s a little less sticky, use a scraper to burnish the transfer tape onto the vinyl. Peel the carrier sheet away leaving the vinyl stuck to the transfer tape.

Step 3. Apply Vinyl to Mylar Balloon

I like to apply the vinyl to mylar balloons before they are blown up. You could apply it afterward if you wanted.

Locate the vinyl approximately in the center of the balloon. Press it down slightly and burnish it with a scraper if needed.

I like to hold the corner of the transfer tape up to make it easier to peel back after the vinyl is stuck down.

Take your time peeling back the transfer tape. Even though we made it less sticky you don’t want to risk tearing your balloon.

Step 5. Inflate Custom Balloon with Vinyl

With the vinyl applied and the transfer tape removed all that is left to do is inflate your custom balloon!

You can inflate the balloon with regular air or helium and then seal it as recommended by the manufacturer. Some balloons require heat to prevent the air from releasing, others just require you to remove the straw you used to inflate the balloon.

As you can see in the photo above, even though my design was only about half the size of the balloon before it was inflated it now takes up most of the front of the balloon. Due to the shape of the mylar balloon and how it puffs up when it’s inflated if the design was any larger it would likely wrinkle and not be as readable.

With vinyl, a single color and a more basic design will be your best bet. You could try doing multiple colors but I wouldn’t do anything too detailed.

For a multi-colored design with detail let’s look at our next custom balloon option!

How to Make Custom Balloons with a White Toner Printer

If you want to make a custom balloon with a design that has multiple colors, I suggest using a white toner print. A white toner print will allow you to get a full-color design and it uses a temperature low enough to apply the design to a mylar balloon!

Step 1: Print White Toner Print and Add Adhesive

You can learn all about printing with a white toner printer and how to marry the adhesive to the print in my white toner printing tutorial. I recommend creating a gang sheet with multiple designs so you don’t waste any of the white toner paper.

Just like the vinyl custom balloon, you don’t want to make the design too large. Make sure the design is only about half the widest parts of the balloon when it is not blown up. You can print several of these designs on one sheet.

After printing, add the sheet to your press and add the b-paper or adhesive.

After adding adhesive, peel back the liner and then trim around the outside edge. Your print is now ready for pressing.

Step 2. Add White Toner Print to Mylar Balloon

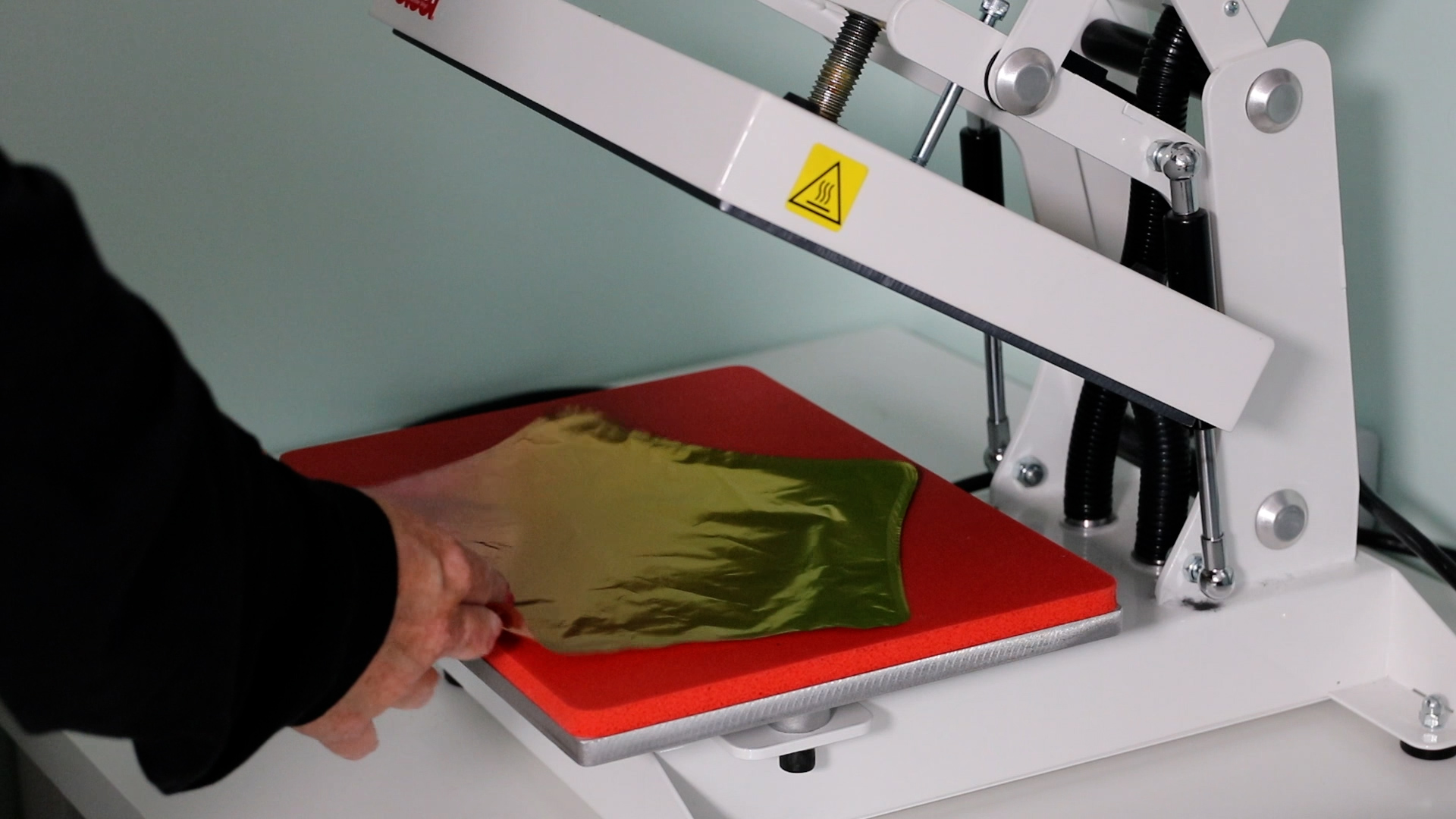

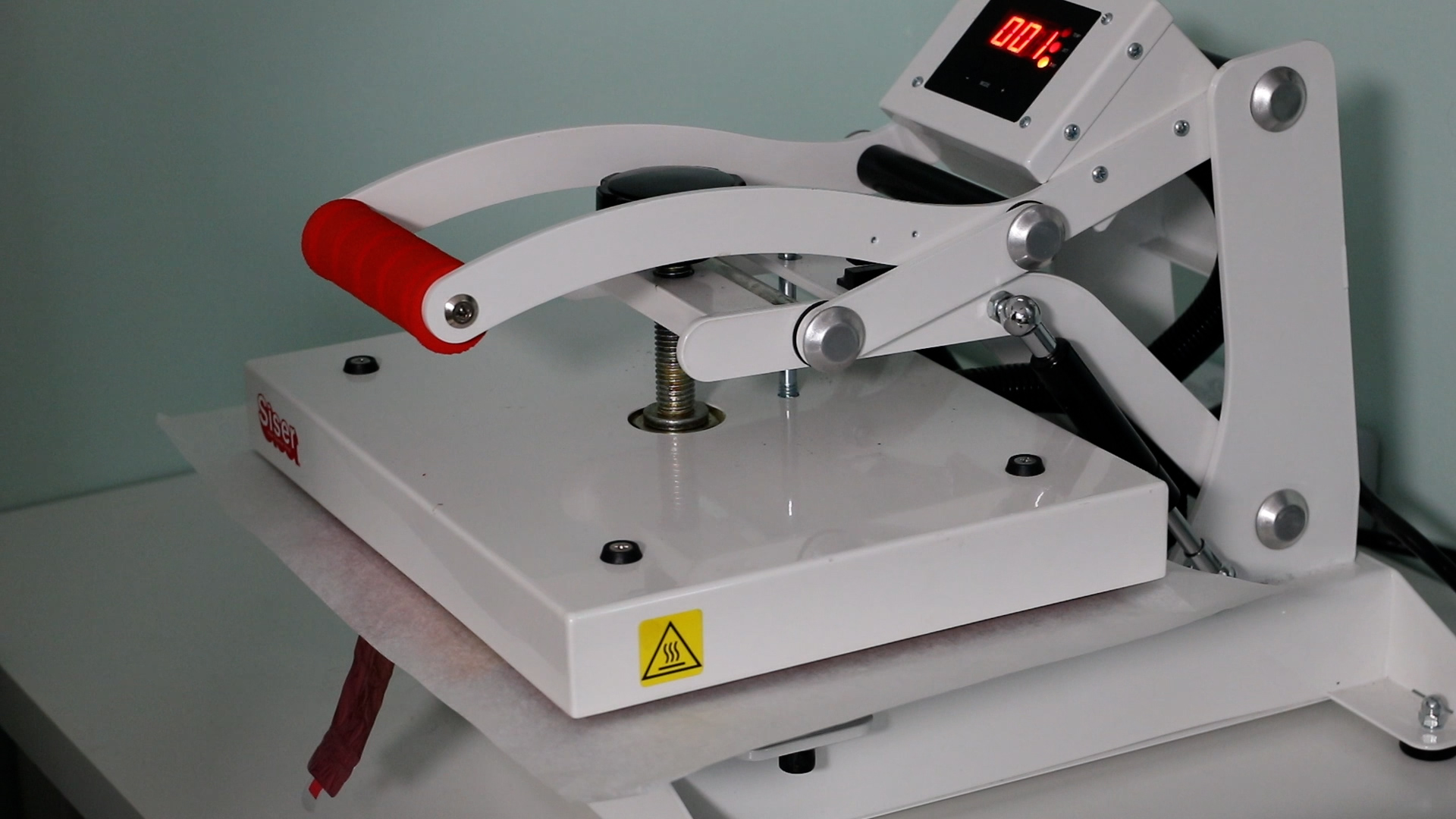

To add the white toner print to the mylar balloon, you need to turn the heat press down to 210 degrees Fahrenheit and set the timer for 10 seconds.

Those are the settings for my balloon. Make sure you double-check the settings recommended for your balloon.

With these balloons, you need to make sure you are not pressing the portion that is for filling the balloon. Find where the filling portion ends and make sure you place your design up above that.

Keep the whole area below where you fill the balloon up outside of the heat press or it will seal the end and you won’t be able to blow it up. Add the print to the balloon in location.

With the print in place, cover the design with the paper that came with the print, or butcher paper and press for 10 seconds at 210 degrees.

Remove the balloon from the press and allow it to cool completely. Once it’s cool, peel back the carrier sheet and the print will remain on the balloon.

Step 3. Prepare the Custom Balloon for Inflation

White toner prints are perfect for custom balloons because the image itself is very thin. It’s just ink and the adhesive. It embeds into the balloon a bit and really looks like it’s part of the balloon.

You can see the carrier sheet left a line around the outside edge. After looking at the balloon inflated, I am not worried about the line because it isn’t really noticeable once the balloon is blown up.

After pressing, my balloon was slightly stuck together. It is not melted just stuck a little bit.

To ensure the best results when the custom balloon is inflated all the way I used a straw to blow a little air into the balloon that I could move around to release the front from the back.

With a little air inside, remove the straw so the air stays in the balloon, and then gently massage the air into the whole balloon to completely release the front from the back.

After you’ve made sure the front and back are no longer stuck together you’re ready to fill the custom balloon all the way up.

Step 4. Inflate Custom Balloons with Air of Your Choice

Depending on the size of your custom balloon and what you’re going to use it for you can blow it up with regular air or with helium.

Because the white toner print is very thin, it looks very professional and feels like it’s part of the balloon itself.

For the best results, make sure your design is not too big. If it is too large it may pucker or wrinkle and look less professional.

Pros and Cons of Making Custom Balloons

There are pros and cons for both custom balloon options I showed you today. Let’s look at both.

Pros and Cons of Custom Balloons with Vinyl

Making a custom mylar balloon with vinyl was actually pretty easy for the design I used.

Vinyl Pros

- Easy to do with a single-color basic design.

- Sticks well and doesn’t go anywhere.

- Can be done with any type of vinyl.

- Don’t have to use heat.

- Don’t need to buy a special printer or order prints.

Vinyl Cons

- Transfer tape can be too sticky.

- More detailed designs may be hard to transfer.

- Multi-colored layered designs may be difficult because of the transfer tape.

- A little thicker than a white toner print, can be felt on the surface.

Pros and Cons of Custom Balloons with White Toner Printer

The white toner printed custom balloons have a couple more steps than a vinyl custom balloon but the results are more professional.

White Toner Printer Pros

- You can easily add any design regardless of how detailed or how many colors.

- Looks very professional, feels like it’s part of the balloon.

- Can be pressed at a very low temperature appropriate for Mylar balloons.

- Doesn’t buckle in the creases because of how thin it is.

- Don’t need to own a Cricut machine.

- Don’t need to weed design.

White Toner Printer Cons

- You may not own a white toner printer and would need to order a print in advance.

- You need to follow the steps very closely to ensure you don’t seal the balloon making it impossible to inflate.

- You need to have a heat press of some sort.

- There is an extra step of separating the front from the back before inflating.

Which should you choose?

I really enjoyed making these custom balloons. Both of my balloons say happy birthday but you can easily create custom balloons for any occasion. Both processes were pretty easy and turned out great with the examples I used.

If you’re looking to make professional-looking custom balloons for an event you’re having or to sell, the white toner printer is the way I would go. I’m a fan of how the pressing process makes the design part of the balloon. Because white toner prints are so thin you can’t even feel them on the surface.

If you don’t own a white toner printer or you’re looking to add a simple design to a balloon, the vinyl balloon does look really nice and would work well for a wide variety of events.

I hope I’ve answered any questions you may have about making custom balloons. If you have any additional questions, leave them in the comments and I will answer them for you!