Ready to learn all about engraving metal with a laser? I’m going to show you different engraving options and how well they work with different metals. If you’ve been wondering if you can engrave metal with your laser, this tutorial will help.

If you’re trying to decide which laser is right for you, make sure you check out my free Laser Ready Course to learn all about different lasers and what they can do.

I am going to talk about metals that are great for engraving and what types of engraving you can do with different lasers. You can watch me go through all of these projects by pressing play on the video below.

Types of Laser Engraving on Metal

The first thing we need to talk about is what type of metal engraving you’re looking for. If you’re imagining deep engraving you can feel, this is done with a high-power laser that melts away some of the material and gives you a deep engraved design.

Not all lasers can do this and most home craft lasers do more of an etching than an engraving. These lasers scratch the surface or remove a portion of the coating on the surface. Let’s look at all of the options!

Option 1. Deep Engraving

I mentioned the deep engraving above. This type of engraving is permanent and you can feel it on the surface of your blank.

True engraving removes a portion of the blank not just a coating or scratching at the surface. This is ONLY with high powered lasers and your laser may not be able to do this function.

Option 2. Etching

Most craft lasers do more of an etching than true engraving. This is when the laser is scratching the surface of the blank.

Etching can fade or be removed over time because it is not deep. This would not be a permanent solution for a blank that is handled a lot.

Option 3. Coating Removal

Another option is removing the coating on the blank. Some metal blanks you purchase have a painted coating applied or you can add a coating.

In this instance, you’re not engraving or even etching the metal blank, you’re just removing that coating.

Often the coating is a color and when you remove it it reveals the metal surface underneath.

This is a popular technique with tumblers but you can do it with other coated metal blanks as well.

Option 4. Bonding

Another engraving option is called bonding. This process involves using a marking spray on the blank and when the laser goes over it the spray bonds to the metal.

When the laser is done you remove the rest of the marking spray and the area you bonded is left on the metal surface.

Laser Options for Engraving

Now that we’ve talked about the different engraving options let’s talk about lasers and what they can do.

Fiber Lasers

A fiber laser is a high-powered laser that can get you that deep metal engraving.

xTool recently came out with the F1 Ultra, it is a combination diode/fiber laser if you want to get true engraving, that may be a good option for you.

CO2 Laser

Another option for engraving is a CO2 laser. Depending on the metal blank you’re using and the material settings you choose you may not get a very deep engraving.

With a CO2 laser, you can at least get an etched or shallow engraving look.

Diode Lasers

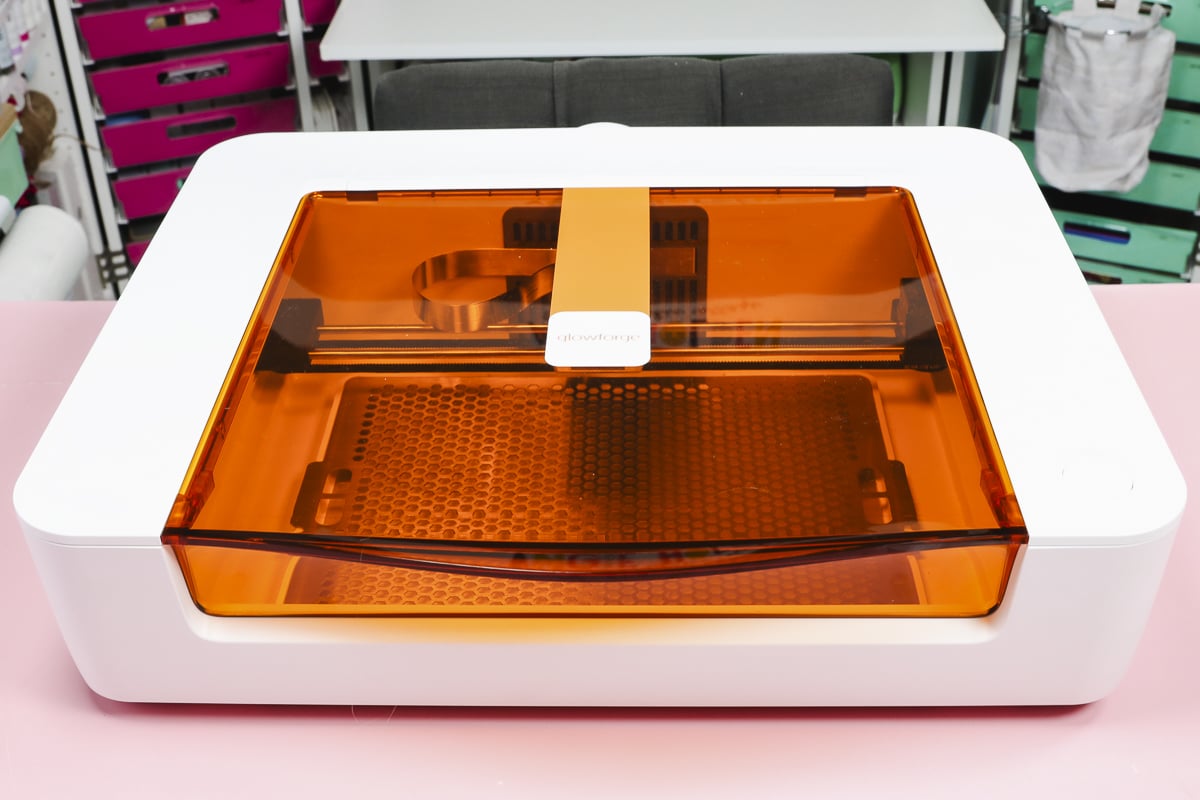

A standard craft laser is likely a Diode laser. If you have the Glowforge Aura, xTool S1, or WeCreat Vision ,you are going to have trouble marking onto metal.

These lasers can’t really mark the shiny metal surface.

With a Diode laser, you can do the coating removal option or the bonding option.

I’ve had good success with the coating removal option with all different wattages of diode lasers.

I didn’t have good luck with the bonding option on my lower-wattage diode lasers like the Glowforge Aura and Spark but a higher-wattage diode laser works with the marking spray.

Infrared Diode Laser Head

Another option with Diode lasers is the Infrared Diode Laser. The WeCreat Vision and xTool S1 are a couple of examples that allow you to switch the laser head to the Infrared laser and you can use it for engraving metal.

The Infrared laser head is going to give you more of an etched or shallow engraving look but it will work on metals that are not coated as well.

What Types of Metal are Best for Engraving with a Laser?

Aluminum is often considered the best material for engraving on a laser but you can engrave steel, stainless steel, copper, gold, and more. You are not limited on metal surfaces if you have something like a fiber laser.

Depending on the type of laser you have you may be restricted on what you can engrave or etch. Some lasers can only engrave something with a coating or marking on it.

Project Examples

Let’s look at some project examples.

Metal Blanks Used

Uncoated Metal Bracelet

This metal bracelet blank is uncoated and this is what happened when I tried to engrave it with my Glowforge Spark.

I tried to etch this blank with an engraving setting and the Spark did not mark the surface at all, you can’t even tell that I tried to engrave it.

I tried various colors of metal and sometimes it would mark it but it was not consistent.

Some areas were etched a little bit but it skipped around, almost like the light reflected and threw off the laser causing it to skip.

Masked Metal Bracelet Blank

Because I wasn’t having success with the uncoated blank, I decided to try adding a masking to it to see if it would do a better job.

With the masking on it looks like it did really well but when I removed the masking it was once again inconsistent. Some areas are marked and others are not at all.

Uncoated Metal Charms

The Glowforge Spark is a six-watt diode laser so I wanted to try other uncoated blanks with my xTool 20-watt to see how they would do.

I used the same 20-watt xTool laser and the same setting on all of these blanks and had different results.

On the silver disk when held a certain way you can see the engraving but you cannot feel it at all on the surface. Basically, it appears to have just removed some of the coating.

The other two metals didn’t do anything at all, you can’t even tell they were in the laser.

With a Diode laser, you can get very inconsistent results. You may find some metals that work and with others, you may get inconsistent results.

Coated Metal Blanks

Because of the inconsistent results with engraving or etching uncoated metals with a diode laser, I prefer to use coated blanks.

Removing the coating from these blanks gives the look of engraving without having to have a higher-powered laser.

This option is permanent but not quite as permanent as actual engraving. The coating itself can wear off resulting in the whole blank looking like a blank metal piece.

This is a great way to mark metal if you only have a diode laser, especially a low-watt diode.

Metal Blanks with Marking Spray Applied

For this next example, I am using black laser marking spray. Spray the marking spray over the metal in a nice even coat and then place the blanks in the laser.

First, I have an example of what happens when it doesn’t work.

For the first example, I used my low-watt Glowforge Spark diode laser. You can see the marking from the laser on the spray coating but when I rub the paint off nothing has bonded to the metal.

I used the same technique with my xTool S1, 20-watt diode laser, and when I wiped away the paint the black markings were bonded to the metal.

This black marking is permanent, however, it would not be as permanent as true engraving.

Engraving with an Infrared Laser Head

If you have the WeCreat Vision or xTool, you can change out the laser head for an infrared diode laser head.

The infrared laser head is a lower wattage but because it is an infrared diode it will do shallow engraving or etching on metal.

I had success engraving on a small uncoated metal blank with the infrared laser and you can actually feel the engraving on the blank. That means it is doing a shallow engraving, not just etching or removing a coating.

Choosing a Laser for Engraving Metal

Now you have options for engraving metal with a laser no matter which type of laser you have. There are options available even if you have a low-watt diode laser.

If you’re looking at purchasing a laser, specifically for engraving metal I hope I’ve helped answer questions you may have about which one would be best for your needs.

I’m a fan of a pros and cons list to help make sure the laser you’re looking at can do what you need it to and also fit within the budget or space restrictions you may have.

If you have any additional questions about engraving metal with a laser. leave them in the comments and I’ll be happy to answer them for you.